|

|

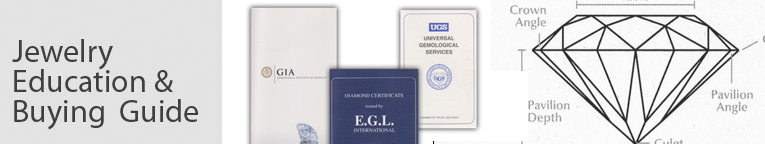

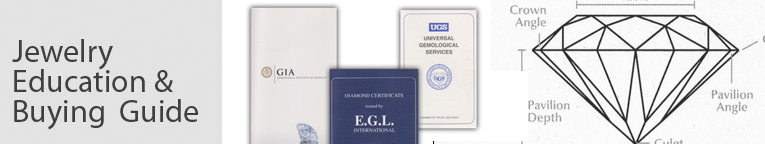

Sndgems jewelry guides are easy to use, interesting and helpful guide to buying jewelry online. Our jewelry guides are indispensable guide to judging jewelry characterstics, distinguishing genuine from imitation, making wise choices, useful to all type of consumers, from professional jewelry to online searchers. Our diamond guides help everyone in viewing diamonds as gemologists, diamond experts, diamond dealers, experienced lapidaries,

diamond buyers and online customers. Our diamond guides dissects each aspect of diamond value in detail with a wealth of diamond grading information. Our gemstone guides help everyone in viewing colored gemstones as gemologists, gem dealers, experienced lapidaries, gem buyers and online customers. Our gemstone guides dissects each aspect of ruby, sapphire, ruby value in detail with a wealth of gemstone grading information. Our guides offers step-by-step instructions for how to examine

and judge the quality and craftsmanship and materials even if you dont know anything about jewelry. If you're thinking of buying jewelry online this guide is a best place to start. Our guides will help you to know about jewelry details such as finishes, settings, flaws and fakes. Our guides cover diamonds, gemstones, jewelry craftsmanship, treatments, diamond and gems sources, appraisals. There is something for everyone.

Jewelry Making - How is Our Fine Jewelry Made

There are four basic methods of making jewelry: casting, die-struck, electroforming and hand fabrication.

Jewelry is made by either punching components out of metal by a machine or by forming casting molten metal into a mold. The metal of machine made jewelry will be harder and denser and would wear better.

Lost Wax Casting

Lost wax casting is an ancient art. The technique was first employed by the early Egyptians but it was also independently discovered and used tribal artists in South America who used it to cast pre-Columbian gold. It was rediscovered by the great Renaissance goldsmith Benvenuto Cellini. While modern versions of the lost wax process employee a few differences, such as industrial vacuums to pull the molten gold down into the mold, the lost wax method as used today is really very similar to that employed by the goldsmiths of Egypt and the pre-Columbian tribes.

The Lost wax method is practical for casting both gold and silver alloys. Although it is most commonly used for rings and bracelets, the lost wax process can be used for casting a variety of objects. This method is currently used to create about 60% of all karat gold jewelry, as well as a significant part of all silver jewelry, enabling manufacturers to produce pieces in multiple numbers at a favorable production cost. The lost wax method allows jewelry artists to copy the finest detail into a gold casting. The jewelry produced by casting can also be subject to further treatment by soldering on additional items, etc. The modern version of the lost wax casting process can be described as follows:

1) From an original design, a model is made in metal. A rubber mold is then made from the model.

2) From this rubber mold multiple copies are made in wax. The wax copies are attached together by a connecting sprue. A group of wax copies are attached together to form a what is called a tree.

3) The tree is then placed in metal flask and covered with plaster of Paris. Once it hardens, the plaster mold is then heated in an oven. The wax melts and is lost, leaving a hollow plaster mold.

4) Molten gold is then poured into the mold as the entire mold is placed in a vacuum the vacuum action draws the gold down into every crevice of the mold forming a perfect copy of the original design.

5) The plaster is then broken and washed away from the now cooled gold casting. The individual gold items are now ready to be cut from the treaty for hand finishing and polishing.

Now if the ancient and primitive peoples of Egypt and South America could do lost wax casting, and produce beautiful works of art, then so can you - with the proper tools and training. Most of the necessary tools and equipment can be purchased right over the internet, and books are available to teach you what you need to know. Here are the basics of how you can do your own lost wax casting using the pressure of steam.

1) Gold, Silver or other precious metals in a clean and castable form (often used jewelry needs cleaning and melting with borax to remove dirt, corrosion and impurities).

2) A torch powerful enough to melt a few ounces of gold or silver.

3) Lost wax casting investment material (the plaster like stuff).

4) A rubber mixing bowl - it is important to mix your investment material with as few bubbles as possible. The bubbles tend to adhere to the wax model and create bubble bumps on the finished product. Shake or vacuum the material to remove bubbles.

5) Various wax models and extra wax to make access sprues. The jewelry wax material is a special type, not just normal paraffin as is used in candles. It has a known density so that the correct amount of metal can be melted for the casting process.

6) A burn out oven capable of about 800 F, which is used to vaporize the waxes.

7) A "crucible" which in this case is a metal tube, to contain the investment and wax for the whole casting process.

8) A steam generator - usually a metal can which has wet material attached to the inside.

After the wax is made, the sprue attached, the investment poured, and the entire product baked to drive out the wax, molten metal is poured in and the steam unit pressed on top. Steam thus created pushes the metal down into the mold. After a time is waited for the metal to cool and solidify, the casting is put under water and the investment material dissolves away.

As a note, casting molten metal can be very dangerous. Molten metal splattered on clothing or skin quickly causes severe burns. Protection of the eyes and other parts of the body is necessary. Wax vapors can be flammable so precautions need to be taken there as well so that the room is fully ventilated. It is strongly urged that anyone who would like to attempt this process purchase books that provide more detail as to how this casting process is done, and read them carefully. These books will also further explain the necessary safety precautions in detail.

Die Struck

Jewelry is made by either punching components out of metal by a machine. The metal of machine made jewelry will be harder and denser and would wear better.

Electroforming

This is a technique of forming metal objects by electrically depositing the metal over a mold. The mold which may be made of wax, epoxy resin, silicone rubber is removed leaving a metal shell.

Hand Fabrication

This is the oldest way of making jewelry and involves use of hand tools as hammer, saw, solder, filler, carver, setting tools and finishing tools. In Europe most of jewelry is hand made as the jewelry is made from start to finish.

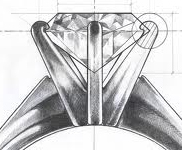

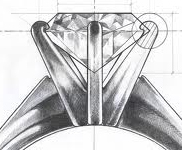

Jewelers take advantage of the various manufacturing techniques by combining manufacturing methods. It is common practice to use a cast head and hand-fabricated shank to make a gem ring. The drawn wire (hand-fabricated) shank has more elasticity than the cast one. The fine details like filigree, engraving, wire design are hand fabricated as it is easier to bend the wire than to carve a wax mold and cast and finish it. A high quality piece often combines casting as well as hand-fabrication.

Components of a Ring

1. Head/Setting-contains the stone

2. Shoulder-Where the head sits

3. Claw- the talons which

keeps the stone in place

4. Shank-the cylinder which goes into your

finger

Sizing -This is when the shank

of a ring is either shortened or lengthened to improve the fit of the ring. The

size required is determined by a set of ring gauges which use the letters of the

alphabet to indicate the size required. ("A" being the smallest). The ring

should fit tightly on the knuckle but still be able to pass over it. To decrease

or size down - a piece of the shank is cut away (approx. 1mm per size decrease)

. To increase or size up the shank is cut and a gap made to accommodate the

additional metal (1mm per size increase)

How is Fine Jewelry models made with Rapid

Prototyping methods or processes?

Jewelry Prototyping

|

Jewelry Molds Using VLT Rubber

Overview - Rapid Jewelry Prototyping Process

The recent introduction of Castaldo®’s VLT™ [Very Low Temperature] molding rubber opens the way to a new time-saving process for jewelry prototyping using molding, by Objet Eden™ 3D Printers Systems. The new rubber allows users Objet users to utilize their PolyJet™ patterns as master models for rapid jewelry prototyping and mold them in as little as one hour. This eliminates the need to go through the time-consuming process of creating a metal master model in the jewelry prototyping process.

Direct casting of resin models made by most rapid prototyping systems do not burn out cleanly. However, using cold-mold compounds that do not damage the pattern and an RP system that supports the specialized material offers the perfect alternative for rapid jewelry prototyping.

Another recently developed alternative method involved making a liquid rubber mold of the model, curing it overnight, injecting the wax, and then casting the wax (another overnight process) to get the master model. Finally, they make a traditional rubber mold, shoot waxes, and start production casting. All together, the process would take more than two days.

Many casters, while still preferring to make a mold of the resin model and shoot waxes are unhappy with the long curing times: quite simply, they want to make their jewelry prototype models as fast as possible.

Jewelry Prototypes - New Methodology

Now this entire process of rapid jewelry prototyping can be done in less than half the time. Rubber can be cured at temperatures ranging from 160°F (71°C) to 180°F (83°C), well below the softening point of most resin materials. At a temperature of 160°F, a standard 3/4-inch mold will be cured and ready for injection in 90 to 120 minutes. At 180°F, that time is further reduced to just 30 to 45 minutes. However, as with traditional casting rubbers, longer curing times mean better molds – the longer the cure, the more likely it is that the rubber will flow into every nook and cranny of the jewelry model to provide detail. In addition, when VLT™ rubber cures, it shrinks just 1.4 percent.

Perhaps one of the greatest benefits of VLT™ rubber in the jewelry prototyping process is that it makes rapid prototyping more useful for mass production. Specifically for the jewelry industry, enabling PolyJet™ models to be used directly as master models is a important development because it offers significant time savings in a market where time can be a vital competitive edge.

Practical Jewelry Prototyping Processing

On a practical level, it is too expensive and time consuming to run a rapid prototyping machine a thousand times in order to create the high number of castings needed. Now, with VLT™ rubber and PolyJet™, a prototype piece can be directly molded, and the subsequent wax models can be used to make thousands of castings.

VLT™ rubber also works well with traditional hand-carved waxes. And, VLT™ rubber is designed specifically for molding – i.e. it acts like any other molding rubber, only at much lower temperatures.

Essentially, the VLT™ and PolyJet™ methodology leverages traditional technology, tools, and techniques. This means there is no one needs to learn anything new, buy new equipment, or train people in new techniques. If you are already doing lost-wax casting, the VLT™ and PolyJet™ methodology fits right in.

How does Jewelry Prototyping work with VLT™ ?

Castaldo® VLT™ Silicone Molding Rubber can be vulcanized at any of a wide range of time and temperature combinations, depending on the characteristics and requirements of the model material. Below are some suggested combinations for a typical mold that is 3/4" / 19 mm thick

88° C / 190° F for 30 minutes

82° C / 180° F for 45 minutes

76° C / 170° F for 60 minutes

71° C / 160° F for 90 minutes

The only change from established mold making techniques required by Castaldo® VLT™ Silicone Molding Rubber may be the need to coat the plastic model with a release spray before vulcanizing to ensure easy release of the model after vulcanization. Teflon® (PTFE) sprays work very well, as do common household cooking oil sprays made with olive oil or canola oil, such as PAM®. Wax models do not need to be sprayed.

Key advantages of Rapid Jewelry Prototypes & VLT

Tools and technology

The VLT™ and PolyJet™ methodology utilizes the simple tools and easy technologies you already have and know how to use.

Easy to work with

VLT™ Silicone Molding Rubber has the consistency of modeling clay or putty, reducing mold packing time to a few minutes. There is no need to cut and shape the pieces to fit the mold frame. Merely pull off a piece with your fingers and push it into the mold frame as desired.

Easy to cut

Molds made of VLT™ rubber are firm, yet they “cut like butter”.

Minimal shrinkage

Rubber shrinkage is only 1.4%

Easy, spray-less release of wax injections

Finished molds require no mold release spray. Wax patterns release easily because the rubber already contains anti-stick compounds.

High-shine finish

Molds made of VLT™ rubber provides waxes with an extremely shiny finish, reducing the polishing work required on your casting.

High tear strength

For a silicone rubber compound, VLT™ rubber is exceptionally high in tear strength, meaning that molds made from it last for years.

Cheaper and easier than RTVs

Room temperature vulcanizing (RTV) compounds require exact measuring and exact mixing. They have limited working times and require vacuum de-bubbling to provide usable molds.

VLT™ Rubber Specifications

Sizes:

Regular strips: 18" x 2 7/8 " x ~3/8" (45.7cm x 7.3cm x ~6mm). Packaged in 5lb (2.27kg) cartons.

Double-wide strips: 18" x 5 3/4" x ~3/8" (45.7cm x 14.5cm x ~6 mm). Packaged in 10Ib (4.5kg) boxes.

Storage:

As with any unvulcanized rubber compound, store away from any source of heat and light. Unvulcanized shelf life is at least one year if properly stored.

Jewelry Prototyping & VLT™ Processes

Castaldo® VLT™ Silicone Molding Rubber is compatible with all mold making techniques, including mold cutting and powder and cream separation molds. It is particularly adaptable to the powder and cream separation processes since the parting line is so easily controlled. For patterns strong enough to resist some pressure, merely push the model into rubber to the desired point. If not satisfied with the results, remove the model, smooth the rubber over with your finger or tool and re-insert the model.

|

|

Figure 1:

The VLT™

Silicone Molding Rubber.

Figure 2: Placing the

Objet model inside the

mold.

Figure 3:

Finished mold

can be complex with even

spiral

plugs.

Figure 4: The resin

Release

Spray.

Figure 5: Objet Jewelry

Models.

Silicone

Molding Rubber is

soft and pliable, with a

consistency like putty or

molding clay.

Place

the Objet model inside

the Silicone Mold.

Placing

and embedding the

rubber onto model.

Curing

Silicone Jewelry Molding

Rubber Molds involves no

mixing, and at low

temperature.

The

Silicone Jewelry Molding

Rubber Molds are then to be

cut and opened by

hand.

Parting

lines are easily

controlled a and corrected

by hand when used with

the

powder separation.

Finished

molds can be

complex with cores, straight

plugs or even spiral

plugs.

|

|

We take advantage of the various manufacturing techniques by combining manufacturing methods. We use a cast head and hand-fabricated shank to make a gem ring. The drawn wire (hand-fabricated) shank has more elasticity than the cast one. The fine details like filigree, engraving, wire design are hand fabricated as it is easier to bend the wire than to carve a wax mold and cast and finish it. Our high quality jewelry often combines casting as well as hand-fabrication.

Basically, the jewelry piece is first created in clay, found objects, anything made of carbons, and/ or special jeweler's wax. Sketches are used for reference,and along a precise hand, special sculpting tools and magnifiers, beautiful and unusual jewelry is created.

The prototype must be perfect before the COLD rubber mold is created.

Only then is the COLD rubber mold of the prototype model (original design) is created.

( A vulcanized rubber jeweler's mold is created after the prototype is cast and finished.)

We use Rapid Jewelry Prototyping Process to make better molds.

The wax model with the sprues is connected to the wax "tree". The tree is a 3 -1/2" to 4" tall about 1/16" thick straight cylinder wax rod. The wax models are wax welded to this. This tree's base or "button" is wider.

When all the wax models are added to the tree, a metal cylinder called a flask is put down on top of the rubber base..

A special plaster like substance called "investment"- which captures the detail of the wax pieces and absorbs great amount of heat- is carefully measured and mixed with water.

The investment is vacuumed on a special vacuum table to remove air bubbles from the investment.(Air bubbles, when cast, become metal bumps that are very time consuming to grind off.)

The investment is painted onto the wax models for the first coat, then the rest of the investment is poured into the flask. After the investment sets up, the calculated weight of the cast waxes is written on the top.

After thoroughly dry, the rubber base is removed from the flask's bottom.

The flasks are loaded into a "burnout oven" or "kiln". The wax is melted out of the flasks, so there is only a hollow cavity left in the flask. This is where the molten metal will be cast in.

NOTE- If all the wax is not entirely melted out of the flask, it can explode when the molten metal is poured in.

Finishing Rough Casting

The centrifugal force casting machine is wound and set. The metal is weighed and measured for each flask,

Foundry person(s) wear Special safety equipment.

The foundry person heats the ceramic crucible with an acetylene/ oxygen torch. The pre-measured metal (usually sterling silver for prototypes) silver casting grain is slowly added and melts. The foundry person adds Borax or flux to clean the metal. Using carbon stirring rod , the foundry person skims off impurities that rise to the silver's surface .The silver's temperature is checked. When ready to cast, silver should look shiny like a mirror... you can actually see your reflection in it . If it is crunchy it needs to be heated more underneath the crucible. If it is too hot and the silver will vaporize.

.

The foundry person, wearing special safety equipment, carefully removes the flask with special tongs from the burnout oven at about 800 degrees Fahrenheit and carefully places the flask in the centrifugal casting machine.

The centrifugal casting machine's pin is quickly released and the metal is centrifugally cast into the flask. When the centrifugal casting machine slows down and the metal looks cherry red, the flask is carefully removed with the tongs and allowed to cool on concrete.. When the cherry red glow disappears, the flask is put into a 5 gallon bucket of water.

The heat from the metal causes the investment (plaster like substance) to boil away from the cast piece.making the water BOILING HOT- similar to a volcano- stand back !

The foundry person carefully removes the cast piece and cools it down with more cool water..

Each cast piece has to be hand cut from the sprue tree.

The silver looks grey now, not at all like what you see in jewelry stores ! The silver turns white after it is cleaned in a mild pickle acid.

Any flashing (excess fin metal) is removed, and the piece's edges are filed, chased (textured) and sanded.

The vulcanized rubber mold is made of the prototype. The vulcanized rubber mold is cut apart and the prototype model is removed and re-polished. It is not used to sell unless it is sold as a "one of a kind" which are much more expensive.

Any findings (bails, jump rings, clasps, hooks, earring posts, or pin backs) are soldered onto the jewelry pieces. Copyright and sterling hallmarks are stamped .

The jewelry piece is finished with buffing compound. cleaned and then recieves a high luster finish with Jeweler's rouge, then ii is steam cleaned.

Understanding the intricate jewelry making process helps us appreciate it even more !

Selecting the Setting

The beauty and craftsmanship of a

ring depends a lot on the stone type and quality of the setting. So it

is very important to pay attention to the setting type that is used while

designing or purchasing a ring. We

need to know facts like whether the metal will hold the stone evenly with a

smooth and fine finish. Will the stone be held firmly in the setting? etc An

understanding of the setting types will help us know what will best suit on the

ring to give it a perfect look.

There are two basic types of

settings: Open Settings and Closed Settings.

Open settings are any type of

setting that allows light to enter through the bottom of a faceted or

transparent gemstone. For eg tension setting, prong setting, care setting,

frustum settings. In a closed setting light can only enter the stone from the

top. This type of setting is appropriate for opaque cabochon-cut stones and

highly refractive faceted stones where light can enter through the crown and

table of the stone and be reflected back to the observer from within. For

example bezel setting, pave setting, channel settings.

Some of the most common diamond

setting types that you will find in a jewelry store are as

under. Read More.

Finishes & Decorating Techniques

We create variety and interest in their jewelry is to texturize with different finishes (like bright polish, florentine finish, sating finish)or decorate (embossing, enameling, engraving, filigree, diamonds, gemstones) the metal.

Our Stone Selection Based on Mohs Hardness

The Mohs Scale is used to determine hardness, Hardness is a measure of a mineral's resistance to abrasion and reflects the atomic structure of a mineral. Generally, high scratch resistance is desirable for gemstones, and a Moh's hardness of 7 or higher is important. The principal reason is that a common cause of abrasion is sand, which is silica grit (quartz), and is commonly present in dust. Stones which are softer than quartz are not suitable for everyday use as facetted jewellery gemstones, particularly in rings, although many are beautiful and attractive.

Some gems, such as pearls, coral, turquoise, lapis lazuli, amber, and opal are quite soft, but are usually polished into cabochons or beads, rather than facetted, and therefore do not show scratches so easily.

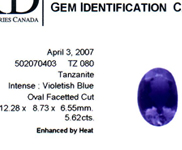

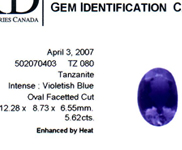

Our Stone Selection Based on Cut, Shape, Carat Weight and Quality

Our Gemologists then select the gemstone based on its cut, shape, carat weight and its quality. Our Gemologists have fine gemstone identification skills like

gemological knowlege, gemology tools and a well trained experience eye. There

are many ways to identify a real gem from a fake one as well as how to evaluate

gemstones quality and its origin. Now that you are familiar with gemstones properties

like Refractive Index, Double Refraction, Birefringence, Specific Gravity, Inclusions it will help in identifying genuine gemstone from fake

stones, evaluating gemstone quality and source of origin. The tables below show

typical inclusions found in genuine gemstones and fake stones as well as have

unique Refractive Index, Double Refraction, Birefringence and other properties. Every gemstone has its own unique identity and genuine gemstone

identification is a process that involves identifying gemstones structure and

chemical properties. Genuine gemstone identification requires gemological

knowlege, gemology tools and a well trained experience eye. There are many ways

to identify a real gem from a fake one as well as how to evaluate gemstones

quality and its origin. Read More.

Our Bench & Stone Setting Process

Our Bench tools includes Pliers, Cutters & Shears, Ring Stretchers, Vises & Clamps, Bench Blocks, Scribes, Files,

Sanders, Saws & Blades, Hammers, Mandrels, Burnishers, Screwdrivers, and Scoops.

Our Magnifiers & Measuring Tools includes Optivisors, Loupes, Bench Magnifiers, Calipers, Gauges, Rulers, Finger Sizers, Mandrels, Diamond Testers, & Scales.

Our Lapidary supplies inclues Diamond Wheels, Sanding Belts, Diamond

Compounds, Blades & Disks.

Our Soldering tools includes Torches, Pickle & Pots, Tweezers, Solder & Fluxes, Blocks, Strikers.

Our Polishing tools includes Dust Collectors, Polishing Motors, Flex-Shafts,

Arbors, Wheels, Compounds, Ring Cones & Buffs, Cones, Mandrels,

Kits, Burs,

Drills, Silicone & Pumice Wheels, UltraSonics, Solutions, Jewelry

Cleaners, Sprays, Tarnish Removers & Cloths.

The notch has to be big enough to accept the "girdle" of the

gemstone. The girdle of the gemstone is the widest part of the stone as shown to

right.

The second consideration in selecting your materials is to avoid

gemstones with a wide or fat girdle. The girdle should be no wider than 1mm and

preferably not that wide. Any gemstone with a girdle that is wider than 1mm is

not a good candidate for setting by anyone but a professional.

When our gemstone and setting ready, we position the gemstone with the

table flat on your work surface and position the setting upside down on the work

surface as shown to the left.

We test whether the setting is properly shaped to hold the

gemstone. Lift the setting and position it over the gemstone gently. Do not push

down yet, just lightly position the stone. When the setting is ready for our

gemstone, the prongs of the setting will be about 0.5mm smaller than the gemstone

itself. You want the prongs so that they setting will require some pressure to

snap into place. That way the stone will be held firmly by the setting. In most

cases with larger gemstones, the setting will accommodate a gemstone that is

about 1mm larger than the size indicated.

Our Fine Jewelry Making Process

Our jewelry is finely handcrafted in platinum or gold mountings ornamented with

certified diamonds and fine genuine gemstones from the best mines in the world. Our jewelry is hand-crafted with delicate milgraining and masterfully

hand-engraved. Diamonds are precision set with delicate milgrain, engraving

details in our jewelry. Our gemstones and diamonds are bright and sparkling set and are set in platinum

or gold and finished with fine milgraining and exquisite hand-engraving. We use high-quality round brilliant-cut diamonds that are exquisitely set in our jewelry with vintage details expertly channel

set in delicate, handmade settings. Hand-engraved scrolls decorate our jewelry.

|

|

| |

|

|

|

|

Gemstone Education

|

|

|

|

|

Diamond Education

|

|

|

|

|

Jewelry Education

|

|

|

|

|

Metals Education

|

|

|

|

|

|

|

|

|

|

Settings Education

|

|

|

|

|

Designs Styles Education

|

|

|

|

|

Ring Size Education

|

|

|

|

|

Certification Education

|

|

|

|

|

|

|

|

|

|

Authencity Education

|

|

|

|

|

Genuine Gems Education

|

|

|

|

|

Buying Online Education

|

|

|

|

|

Jewelry Care Education

|

|

|

|

|

|

|

|

|

|

Gems Care Education

|

|

|

|

|

Company Info Education

|

|

|

|

|

Sapphire Jewelry Advice

|

|

|

|

|

Emerald Jewelry Advice

|

|

|

|

|

|

|

|

|

|

Ruby Jewelry Education

|

|

|

|

|

Antique Jewelry Advice

|

|

|

|

|

Gems Mining Education

|

|

|

|

|

Eco-Friendly Education

|

|

|

|

| Online Shopping Tips - How to Buy Authentic Jewelry, Genuine Gemstones, Natural Diamonds & Real Gold |

|

What is a Genuine Gemstone? Know All About Genuine Gemstones. Read More.

|

|

What is Authentic Jewelry? Know All About Authentic. Read More.

|

|

What is Certified Jewelry? Know All About Certified Jewelry. Read More.

|

|

What is Fine Designer Jewelry? Know All About Fine Jewelry. Read More.

|

|

Genuine Gemstones Identification? Know All About Fine Genuine Gemstones. Read More.

|

|

What is Real Gold, Platinum, Silver, Palladium or Fake Gold Filled, Gold Plated? Know All About Real Gold, Platinum, Silver, Palladium, Platinum, Silver, Palladium. Read More.

|

|

Jewelry Caring & Cleaning, Ruby Jewelry Caring & Cleaning, Sapphire Jewelry Caring & Cleaning, Emerald Jewelry Caring & Cleaning, Diamond Caring & Cleaning. Read More.

|

|

Genuine Diamond Testers, Genuine Gemstones Testers, Real Metal Testers, Authentic Jewelry Testers. ? Know All About Testers to Identify Natural Diamonds, Genuine Gemstones, Real Metals and Authentic Jewelry. Read More.

|

| Sndgems Jewelry Trade Affiliations, Read More and Conflict-Free Diamonds. Read More. |

| Celebrity News - Red Carpet, Oscars, Celebrity Jewelry. Read More. |

| Fine-Quality Burma Ruby, Ceylon Ruby, Kashmir Sapphire, Burma Sapphie, Columbian Emerald Guides. Read More. |

| Complete Online Shopping Guide to ensure safe shopping, getting quality value product with money back guarantee when shopping online for jewelry. Read More. |

|

Identification of Synthetic or Fake Emeralds from Genuine Emeralds Guidelines. Read More.

|

|

Identification of Synthetic or Fake Rubies and Sapphires from Genuine Rubies and Sapphires Guides. Read More.

|

| Identification of Ruby, Sapphire Sources - If they're from Burma, Ceylon or Thailand. Read More. |

| Identification of Emerald Sources - If they're from Columbia, Zambia, Brazil, Africa. Read More. |

| Gemstone Buying Guides - How to Evaluate, Identify & Select Genuine Gemstones of Good Quality. Read More. |

|

Gemology 101: Gemologists Identification & Valuation of Gemstones Diamonds. Read More.

|

|

Identification of Synthetic or Fake Imitation Diamonds from Genuine Diamonds Buying Guides. Read More.

|

|

Jewelry Appraisal Education Center - What's Your Jewelry Worth? Jewelry Appraisal, Diamond and Gemstone Appraisals Guidance. Authentic Jewelry: Certified Diamond & Genuine Gemstone Jewelry. Read More.

|

|

Learn about Diamond Ring Styles and Designs – Choose your Perfect Engagement Ring, Anniversary Ring or Wedding Ring. Learn More.

|

| Jewelry as a gift for your Man – An elaborate Men’s Jewelry Buying Guide. Read More. |

| Sterling Silver - A brief look into its History & Buying Guide. Read More. |

|

The Worlds Top Jewelry Stores, Online Shopping Guides. Read More.

|

| Colors of Gold and Color Gold Jewelry. Read More. |

| Glossary of art terms to help you understand and buy art. Read More. |

| Complete Online Shopping Guide to ensure safe, secure online jewelry shopping. Read More. |

|

|

TR>